Cobot-Schweißen: der Hebel für den Mittelstand

Die beste Cobot-Schweißlösung vom Marktführer. Investitionssicher und Effektiv.

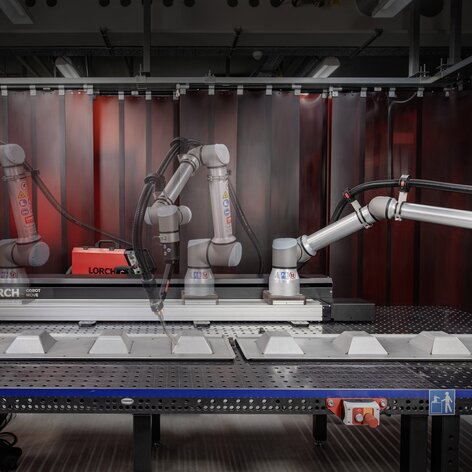

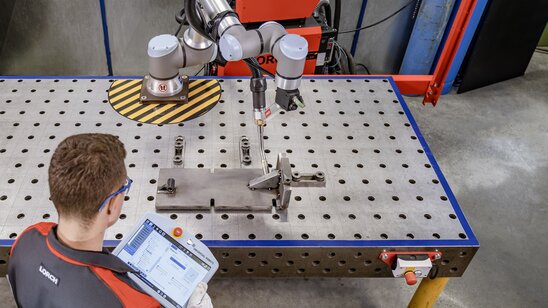

Cobot-Schweißen ist kollaboratives Roboterschweißen für den Mittelstand: schnell, flexibel, wirtschaftlich – ein System, geschaffen für die Automatisierung von kleinen und mittleren Serien. Der Schweißer bleibt bei dieser Form der Schweißautomatisierung Chef des Systems. Der Cobot führt die Anweisungen perfekt und präzise aus. Beide arbeiten Hand in Hand. Das macht den Arbeitsplatz attraktiver, entlastet den Schweißer und führt zu einer Produktivitäts- und Qualitätssteigerung im Unternehmen. Im Vergleich mit anderen Automatisierungslösungen sind Ihre Investitionskosten deutlich geringer als beim weitaus weniger flexiblen Industrieroboterschweißen.

Die Antwort auf

- Fachkräftemangel in der Schweißbranche

- Kostendruck durch internationalen Wettbewerb

- Technologielücken durch unsichere und hohe Investitionskosten

Erstklassige Schweißtechnik und maximaler Service.

Eine Welt für Gewinner: Alles greift ineinander – das Ergebnis ist Spitzenleistung.

Die Lorch Cobot Welding World ermöglicht einen einfachen Einstieg in die Schweißautomatisierung für den Mittelstand. Mit unserem myCobot Systembaukasten bieten wir Ihnen individuelle Komplettlösungen an, die sich leicht in Ihre Arbeitsabläufe integrieren. Intelligente Software, perfekte Prozesse und ein internationales Partnernetz machen den Unterschied für Ihr Projekt.

Jetzt neu: flexibel alle Komponenten zusammenstellen

Der Systembaukasten: myCobot

Die neue Automatisierungslösung myCobot sorgt mit System und Plug-and-Weld-Anspruch für genau die Möglichkeiten zur Individualisierung, die von vielen Kunden praxiserprobt sind und echten Nutzen sicherstellen. Ein Systembaukasten, der Ihnen genau an den richtigen Stellen die Wahl lässt, aber nur wirtschaftlich lohnenswerte Optionen bietet. Schnelle Armortisation, einfache Handhabung für Ihren Schweißer und ganz wichtig: genau für Ihre individuelle Anwendung passend! myCobot ist das Versprechen: die beste Automatisierungslösung für Sie – ganz ohne Risiko.

DIGITALE COBOT VORFÜHRUNG.

Bequem am Bildschirm.

Sie möchten sich digital über die Möglichkeiten und Vorteile der Lorch Cobot Welding Solutions informieren?

Dann buchen Sie jetzt ganz einfach Ihren kostenlosen Online-Termin. Die Vorführung und Beratung erfolgt durch unseren Cobot Spezialisten. Im Fokus stehen hierbei unsere Lösungen für Ihre spezifischen Anwendungsfälle.

COBOT LIVE DEMO.

Wir kommen zu Ihnen.

Sie wollen den Cobot live erleben, bevor er Ihre Fertigung unterstützt? Kein Problem!

Unser Cobot-Truck ist in ganz Deutschland, hauptsächlich jedoch in Süddeutschland, unterwegs und demonstriert die Vorteile der Lorch Cobot Welding Solutions direkt bei Ihnen vor Ort – bei Bedarf auch an Ihren eigenen Bauteilen!

Schreiben uns eine E-Mail an cobot-truck@lorch.eu und unser Truck ist schon so gut wie auf dem Weg zu Ihnen.

Unschlagbares Team:

Die passende Lösung für jede Herausforderung.

Werden die fünf häufigsten Gründe für Verletzungen an Produktionsarbeitsplätzen betrachtet, dann lassen sich 8 % auf monotone Bewegungsabläufe und 24 % auf Überanstrengung zurückführen. Die aktuelle Cobot-Serie vom Marktführer Universal Robots entlastet nicht nur Ihr Team von diesen Aufgaben, sondern eröffnet in Kombination mit unserer Software Lorch Cobotronic neue Dimensionen bei der Bearbeitung Ihrer Schweißaufgaben. Cobot-Schweißen ist jetzt noch intuitiver, präziser und komfortabler!

Höchste Qualität für den praxistauglichen Einsatz. Schnell einsetzbar und intuitiv bedienbar für konstant hochwertige Schweißergebnisse. Und immer mit dem Ziel, für Sie die bessere und wirtschaftlichere Lösung zu schaffen.

Die Software für maximalen Komfort und höchste Effizienz.

Lorch Cobotronic macht den Unterschied.

Was die Lorch Cobot Welding World maßgeblich von anderen Cobot-Lösungen unterscheidet, ist ihre herausragende Software. Sie ist von unseren erfahrenen Schweißexperten perfekt auf die Schweißtechnologie und damit auf Ihre Bedürfnisse abgestimmt – durch maximale Benutzerfreundlichkeit und intuitives Handling fertigen Sie effizienter.

Der Funktionsumfang wird durch Updates und Weiterentwicklungen kontinuierlich erweitert – und das Ganze in 12 verschiedenen Sprachen!

Intuitive Bedienung für schnelles Einrichten und Optimieren.

Spielend leicht zum Ziel.

Die einfache und intuitive Bedienung der Cobotronic-Software ermöglicht es Anwendern in kürzester Zeit, Schweißparameter einzustellen und zu optimieren. Die Auswahl aus drei praktischen Modi ist hierbei eine große Hilfe. Mit dem Assistenzmodus liefert die Software je nach gewählter Anwendung Parametervorschläge für optimale Schweißergebnisse.

Finden Sie mit uns genau die richtige Lösung für Ihre Produktion.

Gemeinsam mit den Cobot-Experten von Lorch können Sie sich genau die Cobot-Lösung zusammen stellen, die Sie brauchen.

Weitere Fragen oder Themen? Unsere Produktexperten stehen schon in den Startlöchern: einfach Kontaktformular ausfüllen und abschicken.

* Pflichtfeld

Geballte Schweißkompetenz.

Egal, ob MIG-MAG oder WIG – immer beste Ergebnisse erzielen.

Für maximale Performance: S5 RoboMIG XT.

MIG-MAG-Schweißen auf höchstem Niveau.

Die leistungsstarke S5-RoboMIG XT ermöglicht es Ihnen durch die vollständige FullProcess Austattung und blitzschneller Regelungstechnologie, nahezu alles zu schweißen, was Sie schweißen wollen – mit höchster Effizienz. Modernste Prozessortechnik sorgt für ein optimales Zusammenspiel aller am Schweißprozess beteiligten Parameter und Komponenten und führt zu maximaler Lichtbogenperformance. Dabei werden Spitzenwerte in der Lichtbogenkontrolle erzeugt und optimale Schweißergebnisse für alle Materialien reproduzierbar erreicht.

Beste Lichtbogeneigenschaften:

V30 RoboTIG.

WIG-Schweißen mit herausragender Performance – und das bei hoher Einschaltdauer und Leistung, das sind die Kerneigenschaften der V30 RoboTIG AC/DC.

Die berührungslose HF-Zündung garantiert eine erhöhte Lichtbogenstabilität sowie einen optimierten Werkstoffübergang. Dank hervorragender Zündeigenschaften ist diese Anlage perfekt geeignet für den automatisierten Betrieb. Die integrierte Fast-Puls-Technologie sorgt außerdem für höchste Effizienz bei der WIG-Schweißautomatisierung. Eine überragende WIG-Technik sowie die bewährte Inverter-Technologie sorgen für optimale Praxistauglichkeit und Produktivität beim automatisierten Schweißen.

FullProcess – für jede Cobot-Lösung.

Die innovativen Schweißprozesse von Lorch.

Geschwindigkeit, Qualität, Einbrand, Nahtoptik – kurz: eine perfekte Schweißnaht und das bei unterschiedlichsten Schweißpositionen erfordert hohe Ansprüche an den Schweißprozess. Unsere Ingenieure haben basierend auf Erfahrungen aus der industriellen Praxis sowie den Wünschen vieler Anwender für Sie herausragende MIG-MAG Prozessinnovationen entwickelt. Das Ergebnis: die Lorch Speed-Prozesse steigern deutlich Ihre Schweißgeschwindigkeit, vereinfachen den Prozess spürbar und ermöglichen eine Produktivität, die ihresgleichen sucht.

- Mehr Geschwindigkeit

- Bessere Nahtqualität

- Höherer Einbrand

- Schönere Optik der Schweißnähte

- Weniger Schweißrauchemissionen

- Weniger Lärmbelastung

- Höhere Ergebnissicherheit durch bessere Prozesskontrolle

Ihr perfekter Start ins digitale Zeitalter.

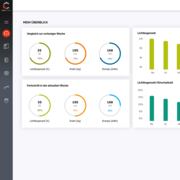

Mit Lorch Connect Schweißprozesse digitalisieren, analysieren und zielsicher optimieren.

Der Einstieg in die Lorch Cobot Welding World geht einen Schritt in Richtung Industrie 4.0. Mit dem serienmäßig enthaltenem Lorch Connect Gateway gehen Sie gleich zwei. Nutzen Sie Lorch Connect, die einfache und kostengünstige Cloud-Lösung für die zuverlässige Erfassung und Analyse Ihrer Schweißfertigungsdaten ganz komfortabel und ohne Zusatzkosten!

Gerade für die Automatisierung ist Performance und Analyse sowie die Dokumentation der Ergebnisse wichtig. Sie erhalten für 1 Jahr einen kostenlosen Zugang zum Lorch Connect Portal und können die digitalen Services völlig risikofrei testen.

Verbinden.

Lorch Connect Gateway an Ihre Lorch Schweißanlage* anschließen und per WLAN oder LAN mit dem Lorch Connect Portal verbinden.

Schweißen.

Fertigungsrelevante Daten werden vom Gateway erfasst und in Echtzeit für Sie an das Lorch Connect Portal übertragen.

Klarsehen.

Das Lorch Connect Portal überall bequem per Webbrowser aufrufen und jederzeit von Auswertungen und Analysen Ihrer Schweißfertigung profitieren.

Download

Sie wollen noch mehr über die Lorch Cobot Welding World erfahren? Details zu Anwendung und Ausstattung finden Sie in unserer Broschüre oder auf unserer Webseite